When it comes to choosing the right materials for various applications, it's important to understand their properties and differences. In the world of engineering plastics, PA 66 and PA 66 GF30 are two commonly used variants. In this article, we'll explore the dissimilarities between PA 66 and PA 66 GF30, shedding light on their composition, characteristics, and applications. So, let's dive in and unravel the disparities between these two materials.

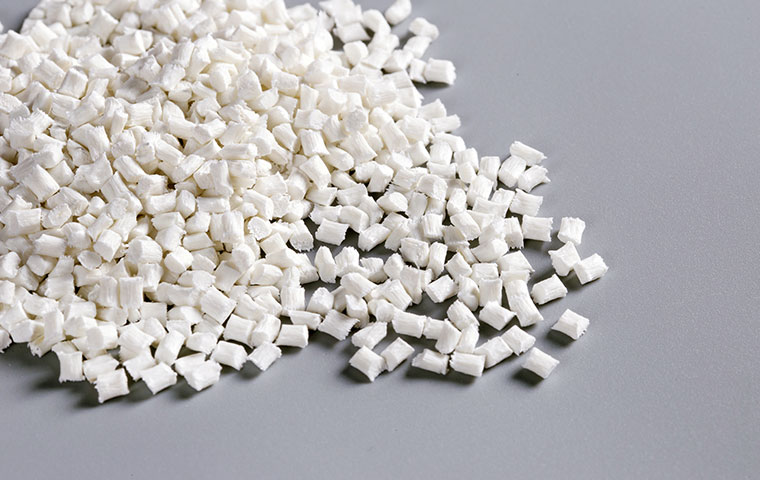

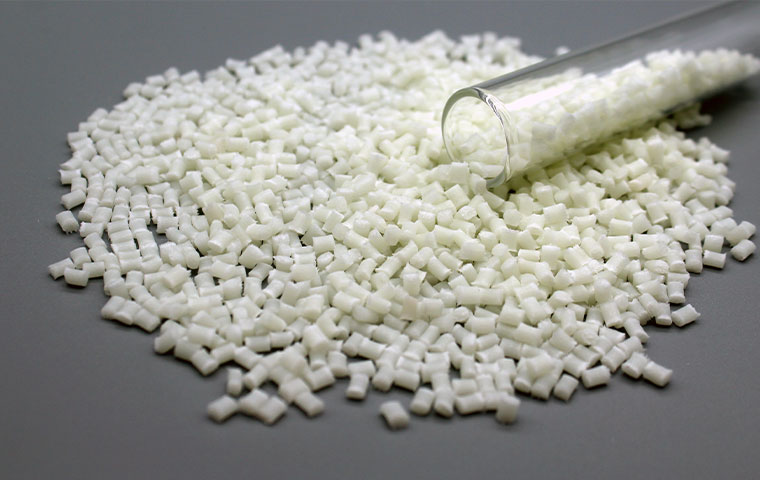

PA 66, also known as Nylon 66, is a versatile thermoplastic material that belongs to the nylon family. It is created by combining hexamethylenediamine and adipic acid, resulting in a polymer with a linear structure. PA 66 exhibits excellent mechanical properties, chemical resistance, and dimensional stability.

PA6 6 GF30 ((PA 66 Glass Fiber Reinforced)) is a modified version of PA 66 that incorporates 30% glass fiber reinforcement. The addition of glass fibers enhances the material's mechanical strength, stiffness, and thermal properties, making it suitable for demanding applications.

By incorporating 30% glass fiber reinforcement, PA 66 GF30 exhibits higher tensile strength, improved impact resistance, and enhanced fatigue resistance compared to PA 66. Both materials provide excellent wear and abrasion resistance, while PA66 GF30 material properties shows reduced creep tendency. The flexibility and toughness of both materials are comparable, falling within the moderate range. Here's a table summarizing the mechanical properties of PA 66 and PA 66 GF30:

| Properties | PA 66 | PA 66 GF30 |

| Tensile Strength | High | Higher than PA 66 |

| Impact Resistance | Good | Enhanced |

| Thermal Stability | Moderate | High |

| Stiffness | Moderate | Increased |

| Chemical Resistance | Excellent | Excellent |

Mechanical Properties Contrast: PA 66 and PA66 GF30

PA 66 finds extensive use in automotive components such as engine covers, fuel lines, and connectors due to its high strength, wear resistance, and dimensional stability. It is also utilized in electrical applications for its insulating properties. In consumer goods, PA 66 is commonly found in toys, sporting equipment, and appliances.

On the other hand, PA 66 GF30, with its improved mechanical properties, finds applications in more demanding environments. It is favored for automotive components like engine mounts, gear wheels, and structural parts that require higher strength and stiffness. Electrical connectors and housings benefit from the enhanced properties of PA 66 GF30. In the industrial machinery sector, it is used for components such as bearings, gears, and pump parts. Additionally, PA 66 GF30 finds its place in electronics and electrical appliances due to its improved performance. It is also chosen for sports and leisure equipment.

In summary, PA 66 and PA 66 GF30 are both valuable engineering plastics with distinctive characteristics. PA 66 offers good overall performance, while PA 66 GF30 provides enhanced mechanical strength and thermal stability due to the incorporation of glass fiber reinforcement. Understanding the differences between these two materials allows engineers and manufacturers to make informed decisions based on the specific requirements of their applications.