The limiting oxygen index (LOI) of ordinary TPU is only 16% to 18%. In case of fire, it will burn quickly and decompose to produce a lot of toxic fumes.

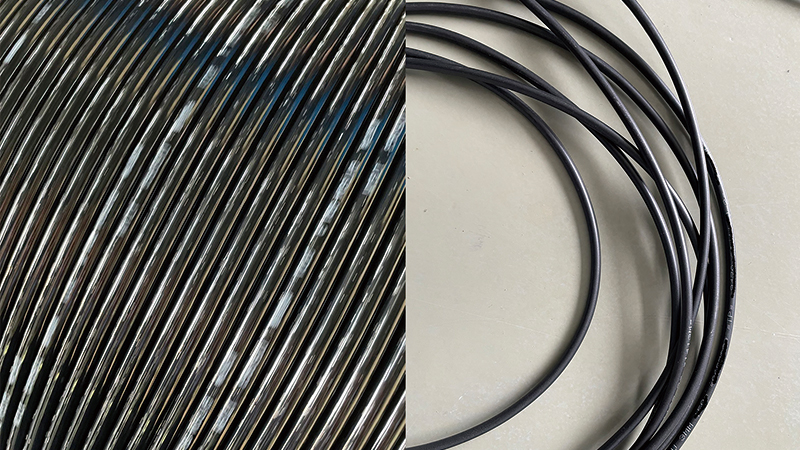

With the advancement of China's "14th Five-Year Plan" development plan and the heating needs of the global cable industry, as well as the rapid development of new energy vehicles and charging piles, Anmei has successfully developed mechanical properties, tear strength, Flame retardant TPU with good thermal aging resistance, good hydrolysis resistance, and excellent flame retardant performance and extrusion process performance.

Several leading companies in the wire and cable industry have tested and verified the charging pile cable produced by Anmei TPU conforms to the standard GB/T33594-2017 of electric vehicle charging cable. The basic physical properties are as follows:

Test Item | GB/T33594-2017 | ANMEI Value | Unit |

Material performance index | ≥20 | 12.5 | Mpa |

Density | ≥300 | % | % |

Tear strength | ≥40 | 41.5 | N/mm |

HEAT AGEING 110℃,168hours | |||

Change rate of tensile strength | ≤30 | -11.9 | % |

Change rate of elongation at break | ≤30 | 4.3 | % |

Resistant to Hydrolysis 80℃,168hours | |||

Change rate of tensile strength | ≤30 | -25.1 | % |

Change rate of elongation at break | ≤30 | 20.8 | % |

Volume resistivity | ≥1X109 | 2.1X1001 | Ω.m |

Low temperature shock | ≤15/30 | 0/30 | - |

Flame retardant grade(3.2mm) | UL94 | V0 | A |

And the environmental performance of lead, cadmium, mercury, DBP and other chemical testing items meet the requirements of electric vehicle charging cable , please contact us to obtain a complete test report.

We can also adjust hardness, flame retardant performance, surface molding requirements of TPU material to meet the practical needs of customers in different scenarios according to the individual needs of customers

TPU product storage

When the dry TPU elastomer material is exposed to the atmosphere,it will quickly absorb moisture because it is a thermoplastic elastomer material with strong hygroscopicity. It is recommended that the aluminum plastic bag be sealed and stored.

Drying of TPU products

In order to ensure the best performance after extrusion, it is recommended that the TPU FR material be dried at 80~110℃ for 2~4h before processing to make sure the moisture content of the particles does not exceed 0.02%.

TPU tinting

It is recommended to use color masterbatch with TPU resin as the carrier, and the recommended amount of color masterbatch is 1%~2%.